Air Purification Technologies

With over 30 years’ expertise in innovative dust management solutions for heavy industry, Propulsa Innovations has developed an air pre-filtration system that uses a low-frequency self-cleaning system.

With the aim of adapting its technology to different industries, the company intends to become the must-have solution for heavy equipment users looking for healthy air management.

Epura System

The technology developed by Propulsa Innovations exponentially increases filter replacement intervals, reducing vehicle downtime and increasing fleet availability in original systems, while surpassing their performance in very dusty environments.

Dust-laden air enters through the base of the Epura systems and passes through a high-efficiency filter, equipped with a Spunbond membrane coated with PTFE. When the Epura system’s filter reaches a saturation level, a cleaning cycle using low-frequency sounds becomes necessary. This is done by stopping and restarting the equipment’s engine, which cleans the filter without any real interruption, with the cleaning cycle lasting an average of 10 seconds.

These innovative systems can be installed on operation cabins (Epura Cabin) and on the air intakes of diesel engines and other industrial filtration equipment (Epura Engine).

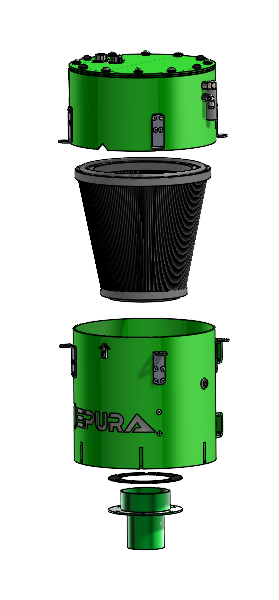

Epura Engine

A High-Performance System

The Epura Engine self-cleaning pre-filtration system keeps the engine and its components protected, improving heavy machinery performance while lowering fuel consumption and minimizing greenhouse gas emissions.

Filtration box

Pre-filtration system that performs cleaning using low-frequency sound.Smart controller

Detects pressure differential and starts the cleaning process.Operator interface

Allows the operator to monitor the status of the system at all times.

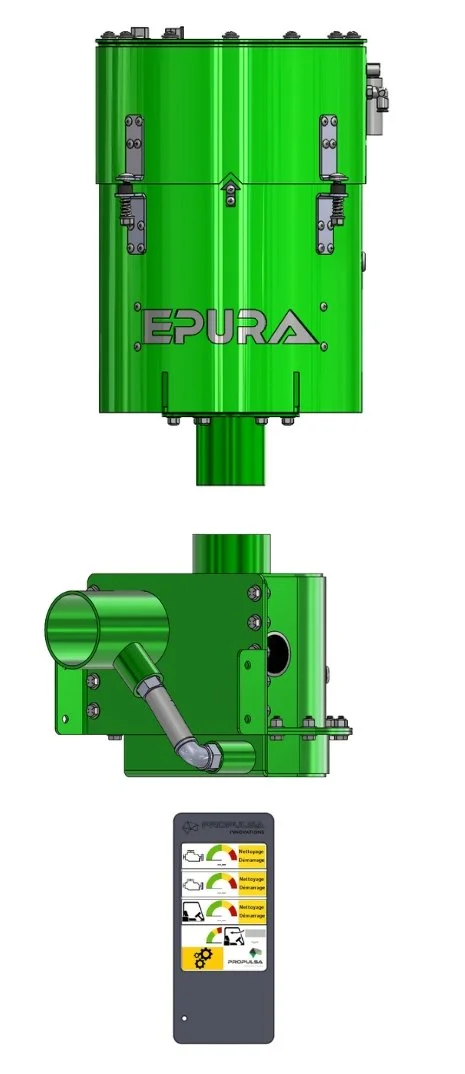

Epura Cabin

A System that Protects

The Epura Cabin pre-filtration system provides constant adjustment of cabin air pressure, ensuring a healthy work environment and a clean air supply for the operator.

Filtration box

Pre-filtration system that performs cleaning using low-frequency sound.

Smart controller

Detects pressure differential and starts the cleaning process.High Performance fan

Adjustable fan ensures stable cabin pressure.Operator interface

Allows the operator to monitor the status of the system at all times.